Standard Operating Procedures | Approved

Jul 02, 2019· Facilities Construction Standard Operating Procedures Index Administration (ADM) Central Control (CC)

WhatsApp)

WhatsApp)

Jul 02, 2019· Facilities Construction Standard Operating Procedures Index Administration (ADM) Central Control (CC)

Sanitation Standard Operating Procedure (SSOP) Responsible Employees. ... etc. (Simple equipment and hand tools are cleaned and sanitized in the same manner, but they do not require disassembly and reassembly.) ... as described in the SOP for Finished Product Storage. Coolers should be at 41º F or colder and freezers should be at 0ºF or colder.

BENCH GRINDER. DO NOT use this equipment unless you have been instructed. in its safe use and operation and have been given permission. PERSONAL PROTECTIVE EQUIPMENT. Safety glasses must be worn at all times in work areas. Long and loose hair must be contained. Hearing protection must be used. Sturdy footwear must be worn at all times in work ...

Standard Operating Procedure – Standard Polisher/Grinder About this SOP This document describes the standard operating pr ocedure for using the polisher/grinders in room 157 Engineering II. It covers hazards, emergency procedures, basic specifications and operating procedures. Who to Contact

ABRASIVE WHEELS/GRINDERS – BENCH, FLOOR, AND HAND ... general tool safety considerations presented in the EHS SOP, Hand and Portable Power Tool Safety. ... • Never clamp a handheld grinder in a vise. • Always engage the OFF switch and wait for the wheel to come to a complete stop

The LC80 HandCrank Disc Mill provides effective performance for limited dry or wet grinding to moderate fineness of coal, chemicals, ores, pharmaceuticals, nuts, grains, and other friable materials. This mill has a painted, cast iron body that mounts by screw clamp to .

Hand and finger damage. Eye, respiratory and hearing damage. ... JOB STEPS • Ensure material to be machined is appropriate size and will mill safely. • Secure material in jaws of vice (remove all debris from vice to ensure material is ... (Ensure this section is completed and copied onto rear of SOP.

Safety precautions while working with machinery •Stop the machine before measuring, cleaning or making any adjustments. •Do not handle metal turnings by hand as they can cause injury. Use brush or rake to remove turnings. •Keep hands away from the cutting head and all moving parts. •Cutting tools and blades must be clean and sharp, so that ...

FRITSCH ONE STEP EAD. FRITSCH is an internationally respected manufacturer of applicationoriented laboratory instruments. Our instruments have been used for decades worldwide for Sample Preparation and Particle Sizing in industry and research laboratories.

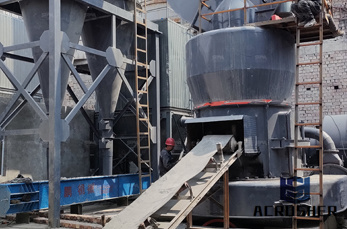

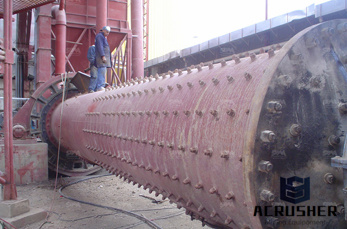

Ball Mill and Grinding Circuit Preparation for StartUP The following items must be checked before the equipment in the Grinding Circuit is started. Check the ore slot feeder for obstruction or hang—ups. Check the ball mill belt feeder for undue buildup of material. Check oil level in ball mill lube oil tanks. Also, check grease level in the mill ring gear spray lube drum.

Standard Operating Procedure (SOP) – ... to tighten cutting bits or tools by hand. Standard Operating Procedure (SOP) – Milling Machine EWU EHS SOP Page 2 of 2 6/12/14 Do not power the machine to tighten or loosen cutting bits or tools. Work pieces and stock must be rigidly fastened to the mill bed with clamps, a vise, or special ...

Bionics Scientific is a leading laboratory ball mill manufacturer in India and offers its customers a fair deal in buying ball mills with facilities of customized size and capacities up to 10 Kg. In standard, these lab scale ball mill machines come in 2Kg, 5Kg and 10 Kg and are sold all over India at highly competitive price. These machines are supplied with steel grinding balls with different ...

This ultra fine grinding mill yields the highest percentage of fine particles within target of any fine mill technology with up to 40% improvements compared to other milling options. Competing technologies typically don''t incorporate twostage size reduction technology like the Fine Grind, so they are simply not equipped to replicate Fine ...

The Autofill system avoids direct contact with LN 2 and makes cryogenic grinding very safe. Its versatility (cryogenic, wet and dry grinding at room temperature) makes the CryoMill the ideal grinder for quantities up to 20 ml. You may also be interested in the High Energy Ball Mill Emax, an entirely new type of mill for high energy input. The ...

Sep 28, 2016· The Hammer and Screen Mill is a highspeed mechanical impact mill designed for continuous size reduction of a wide range of materials for chemical, pharmaceutical, food, mineral, and .

Sep 20, 2019· The 5 Best Hand Operated Grain Mills [Ranked] ... Using a handpowered grain mill, you can do all your grinding in your kitchen, producing flour that contains all of the vitamins and minerals you will need for baking or cooking purposes with the flour .

JET MILL POWDER PROCESSING TECHNOLOGY: THE STURTEVANT SOLUTION. ... nology. Utilizing a unique fluid energy grinding system to generate particleonparticle impact, the Micronizer grinds and classifies powders to micron and submicron sizes in a single operation, in a single grinding chamber. ... for sanitary/pharmaceutical applications ...

List of Standard Operating Procedures (SOPs) for Production/ Manufacturing department for pharmaceutical products manufacturing facility.

Standard Operating Procedure For Manual Capsule Filling Machine SOP for Action to be Taken During Spillage/Breakage of Materials · SOP for Action to be SOP for Automatic Capsule Filling Machine · SOP for Automatic Coating SOP for Manual Glassware Cleaning · SOP for Manufacturing of Tablets and SOP for Procurement, Maintenance and Sub

Working of the Colloidal Mill. The material is placed into the mill though the inlet hopper. It is then passed through the narrow gap between the rotor and stator and thus reduced the fine particle size. A colloid mill is a hydraulic shear producing device. The colloid mill .

A mill is a device that breaks solid materials into smaller pieces by grinding, crushing, or cutting. Such comminution is an important unit operation in many are many different types of mills and many types of materials processed in them. Historically mills were powered by hand (, via a hand crank), working animal (, horse mill), wind or water ().

For over 180 years, Stedman has offered industrial, highquality fine grinders and grinding mills for various industries that are professional grade. Stedman grinding mills are utilized by industries like mining! Our industrial grinding mills are available in various sizes with feed, capacity, and horsepower options. Request your quote today!

Cad Mill Cage Blender Calibration of Dry Bath ... Hand Wash Procedure Handling and Usage of Hazardous Chemicals Handling and Control for Prohibited Items ... SOP in Pharmaceuticals Standard Operating Procedures. For Sample SOP Resources please click here. About Fhyzics. Fhyzics a global leader in business analysis offers business consulting ...

Choosing a Grain Mill or Flour Grinder | In this article Everything Kitchens issues a full comparison of the various electric and manual grain mills we sell. This overview includes models from Family Grain Mill, Wonder Mill, Country Living, L''Equip, and more.

WhatsApp)

WhatsApp)